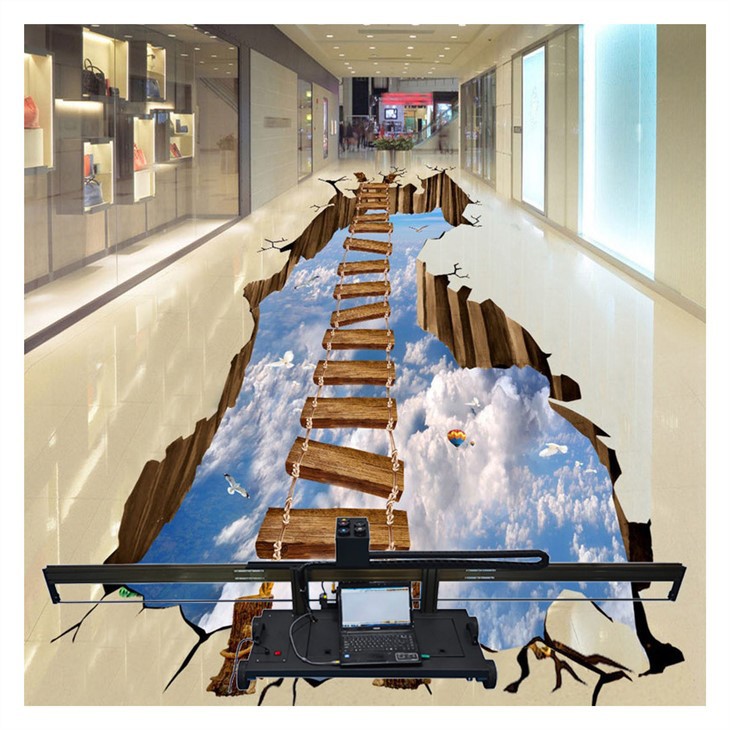

Automatic 3D ground printing Floor Printer Machine

Tanyu Technology: a Professional Floor Printer Manufacturer

Our company was established in 2012 and is an innovative enterprise focusing on the field of wall painting technology.

Variety of Products

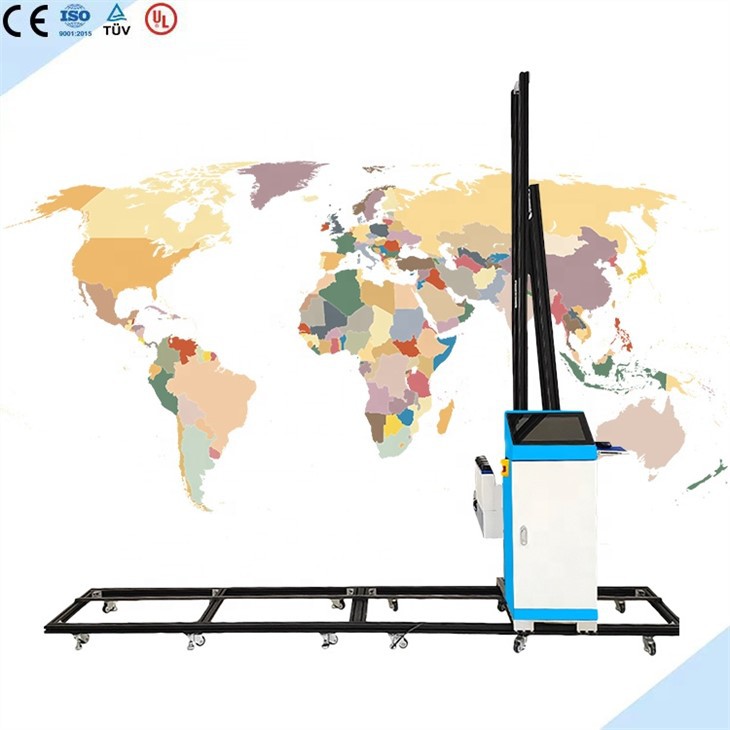

We are committed to providing customers with high-quality wall painting machines and large-format wall decoration solutions. Our products include wall printers, floor printers, wall and floor all-in-one printers, vertical 3D wall printers, vertical wall printers with wheels, etc.

Strong Production Capacity

We have two professional production lines and an independent R&D department. We can provide customers with customized machines and improve equipment as the market changes. Usually, it only takes 5 days for standard machines to be delivered, and 9 to 12 days for customized machines.

Strict Quality Standards

All the suppliers we work with are world-class. Each machine has precise assembly process and strict time control. At the same time, we will conduct strict testing and inspection on each machine before shipment to ensure quality and reliability.

Multiple Professional Certifications

At present, we have many international certifications such as ISO9001 certification, CE certification, SGS certification, etc., and have also obtained more than 10 patent certificates. We have provided services to 1000 customers and received good reviews.

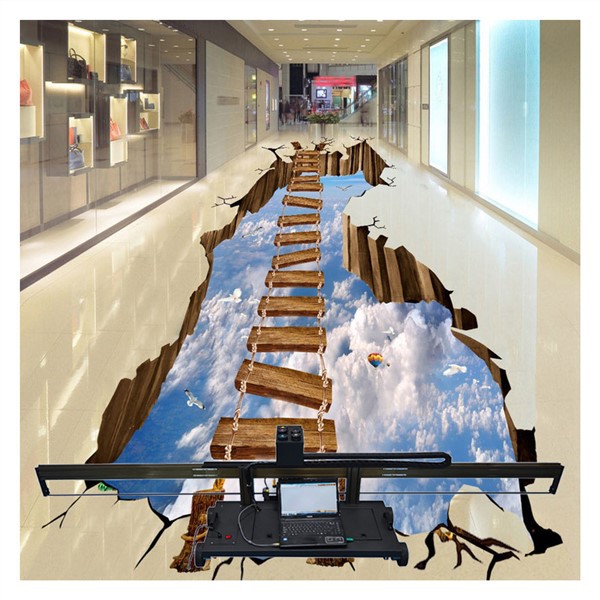

TANYU advertising floor printer can print directly on the floor, the machine width can be customized according to customer requirements. Our standard print to floor width is 2.5m and print width is 2.1m. The floor press can print any format, any size photos, printing resolution up to 1440x2880dpi.

Floor printer is a unique full color digital printing system specifically designed to digital paint any graphics onto floor surfaces. It employs UV technology to print on multiple material floors including wooden floors, cement, asphalt roads, brick walls, lime, epoxy resin, ceramic tiles, brick pavement, plastics, ceramics, etc. With the help of tracing system, the floor printer can print on curved and uneven brick surfaces. In order to ensure print quality, floor printer has installed high-precision sensors that can automatically sense the distance between the print head and the ground. Even on uneven floors, the print head will automatically shrink to maintain the best distance from the floor to ensure the best print quality.

Professional RIP software converts your imported images into machine code, and the printer nozzle sprays CMYKW5 ink. Different inks are mixed at each spot to form the desired color for the image, which is then cured by a UV lamp. From a structural point of view, the floor printer has a wheel-type structure and has unlimited expansion capabilities in the vertical direction. In the horizontal direction, only a fixed width can be printed at a time. If you need to increase the width, you will need to extend the horizontal rails or use the splicing feature to extend the landscape format. The printer nozzle is equipped with 2 sensors that can automatically sense the distance between the nozzle and the ground to maintain the optimal printing distance between the nozzle and the ground while preventing the nozzle from hitting the ground due to uneven ground.

UV Printing

UV printing works on the principle that ultraviolet rays dry the ink instantly. This technique allows the print to dry immediately, which improves print quality and ensures that the print is more resistant to fading or distortion. Thanks to the UV printing technology in the floor printing printer, excellent details and vivid colours are achieved on the floors. Especially in commercial areas, durability and longevity are essential. UV printing meets these needs, making the floor printing printer indispensable in the industry.

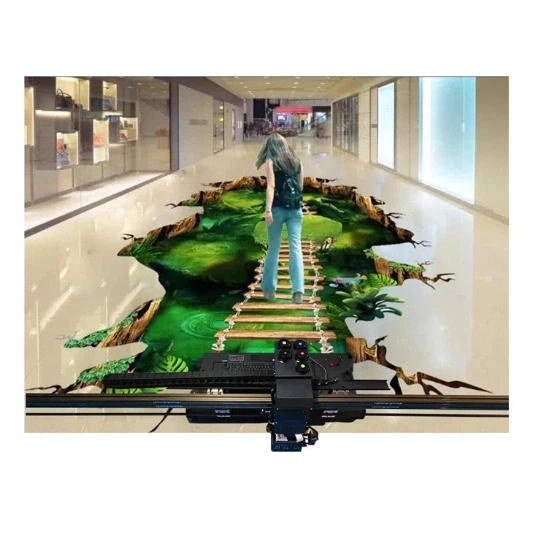

3D Printing and the Revolution in Location Printing

3D printing works on the principle of creating three-dimensional objects layer by layer. The use of 3D printing technology in the floor printing printer allows three-dimensional effects and textures to be added to floors. This is a great advantage for creating unique and eye-catching floors, especially in interior design. Thanks to its 3D printing capability, the floor printer has the potential to go beyond traditional printing techniques to offer customers customised and creative solutions.

Environmental Impact

UV printing technology is an environmentally friendly alternative to traditional solvent-based inks. It creates less waste and minimises the release of harmful emissions into the air. This is a great advantage for companies that attach importance to the principle of sustainability.

Cost Effectiveness

The cost-effectiveness of the floor printer is characterised by both the speed of the printing process and the ability to produce with little material waste. Thanks to the fast drying of UV inks, it is possible to move on to other processes immediately afterwards, which means time savings. 3D printing can add depth and texture to the surface without using specialised materials, which can further reduce costs.

Privatisation and Innovation

One of the biggest innovations brought by the floor printing printer is the customisation capability. 3D printing technology ensures that every project is unique and special. Whether it is a company logo or an original work of art, you can realise your dream designs with a floor printing printer. Furthermore, these printers make it possible to print complex and detailed patterns simply and quickly. It is both time-consuming and costly to realise such designs with traditional printing methods.

Floor Printer Parameters

|

Product |

3D Floor Printing Machine Printer Ground Printer Machine |

|

Print head mold |

Two/Three |

|

Print head type |

Epson (DX10/DX7 ) |

|

Printing Resolution |

720x 720,720x 1440,720x 2008,1440×1440,1440x 2880dpi |

|

INK Type |

UV ink |

|

Colors |

5 colors (CMYK+W) |

|

Print size |

Width 2.5M *Length unlimited |

|

Printing speed |

8~15 square per hour |

|

Printing height |

10-20mm |

|

Curving method |

LED UV lamp |

|

Software |

Photoshop/Ultrarint / Betterprint |

|

Motor |

Servo motor & Stepping motor |

|

Data port |

USB3.0 |

|

Language |

English |

|

image format |

PSD, CDR, JPEG, JPG, PNG, BMP, TIFF, EPS, Al, PDF etc |

|

Operating system |

Microsoft Windows XP/778/9/10 |

|

Power supply |

220V/110V |

|

Operating environment |

0℃-50℃(32°F-122°F)10%-70% |

|

Storage environment |

-21℃-6o℃ (-5°F-140°F)10%-70% |

|

Machine size(L*W*H) |

250*50*60 cm (can be folded) |

|

Net weight |

55kg |

|

Gross Weight |

120 kg |

Versatility

3D UV floor printers can print on a variety of surfaces, including wood, tile, concrete, and even carpet. This means it allows users to create creative and custom designs in a variety of environments including homes, offices, retail spaces and public spaces.

Cost-effectiveness

Compared to traditional methods like painting or installing new flooring, 3D UV floor printing can be a more cost-effective solution. It eliminates the need for expensive materials and labor-intensive processes, making it an attractive option for budget-conscious projects.

Durability

UV-cured inks used in 3D floor printing are highly durable and resistant to fading, scratches, and water damage. Therefore, it ensures that printed designs are long-lasting, even when applied in high-traffic areas.

Time-saving

3D UV floor printing is a fast process that allows for quick installation and minimal downtime. Unlike traditional flooring methods that require drying or curing times, UV printing produces instant results, reducing project timelines significantly.

Customization

With 3D UV floor printing, the design possibilities are virtually endless. Whether you want to replicate natural textures like wood and stone or create intricate patterns and graphics, UV printing offers a high level of customization to suit any design aesthetic.

Environmental-friendly

UV printing is an eco-friendly option compared to traditional flooring methods that may involve harmful chemicals or excessive waste. UV-cured inks are non-toxic and produce minimal VOCs (volatile organic compounds), making them a more sustainable choice for indoor environments.

The floor printer, which has caused a revolutionary change in the printing industry, has a wide range of uses. So where are these printers used? Here are some prominent areas of use:

Advertising and Promotion Sector: Floor printers are used as advertising and promotional materials in a wide range of areas from store floors to fairgrounds, from shopping centres to airports. Thanks to 3D effects, it becomes much easier to attract the attention of potential customers.

Interior Decoration and Design: Floor printer technology is frequently used in the production of specially designed floor coverings, wallpapers and even furniture. The vivid colours offered by UV printing and the depth given by 3D printing give the interiors a unique atmosphere.

Education and Playgrounds: Interactive and fun floors are created by using floor printers in places such as children's playgrounds, sports halls or training centres. It offers both an instructive and entertaining experience for students or visitors.

Art and Exhibitions: Artists and designers have the chance to exhibit their original works with floor printer technology. In museums, galleries or outdoor exhibitions, this technology allows art to be presented in a more impressive way.

Industrial Applications: Floor printers are particularly useful for signage, signposting and security applications. For example, markings on warehouse floors help to make the workflow more organised.

Some Factors to Consider When Purchasing a Floor Printer

When choosing a floor printer, several factors should be considered to ensure that you select the right equipment for your specific needs. Here are some important factors to consider:

Printing Technology: Consider the printing technology used by the floor printer. UV printers are popular for their fast curing times and durability, while latex printers are known for their versatility and eco-friendliness. Choose a technology that aligns with your printing requirements.

Print Quality: Evaluate the print quality of the floor printer, including resolution, color accuracy, and detail reproduction. High-quality prints are essential, especially for applications where fine details or intricate designs are required.

Speed and Productivity: Assess the printing speed and productivity of the floor printer. A faster printing speed can increase efficiency and throughput, allowing you to complete projects more quickly and meet tight deadlines.

Compatibility: Check the compatibility of the floor printer with various media types, such as different flooring materials and textures. Ensure that the printer can effectively print on the surfaces you intend to use, whether it's wood, tiles, concrete, or carpets.

Size and Format: Consider the size and format capabilities of the floor printer. Choose a printer that can accommodate the dimensions of the printing projects you typically work on, whether they are small-scale designs or large-format installations.

Ease of Use and Maintenance: Look for a floor printer that is user-friendly and easy to operate. Consider factors such as intuitive software interfaces, automated maintenance features, and accessibility for routine upkeep and cleaning.

Budget: Evaluate the initial cost of the floor printer, as well as ongoing expenses such as ink, maintenance, and consumables. Consider your budget constraints and weigh the upfront investment against long-term operational costs.

Support and Training: Ensure that the manufacturer provides adequate support, training, and technical assistance for the floor printer. Reliable customer service and training resources can help you maximize the performance and longevity of the equipment.

Environmental Impact: Consider the environmental impact of the floor printer, including energy efficiency, emissions, and waste generation. Opt for printers that use eco-friendly inks, consume minimal energy, and adhere to sustainability standards.

Future Expansion and Upgradability: Think about your future needs and whether the floor printer can accommodate potential growth or upgrades. Choose a printer that offers scalability and the ability to adapt to evolving printing requirements in the long term.

Proper maintenance is crucial for ensuring the optimal performance and longevity of floor printers. Here are some tips to help you maintain your floor printer effectively:

Regular Cleaning: Clean the printer regularly to remove dust, debris, and ink residue that can accumulate on the surfaces. Use manufacturer-recommended cleaning solutions and follow the guidelines provided in the printer's user manual.

Printhead Maintenance: Printheads are critical components of floor printers. Follow the manufacturer's instructions for printhead maintenance, including regular cleaning and purging to prevent clogging. Use recommended cleaning solutions and tools to ensure proper functioning.

Ink Management: Monitor the ink levels regularly and refill or replace cartridges as needed. Use genuine and compatible inks recommended by the printer manufacturer to maintain print quality and prevent potential issues.

Calibration and Alignment: Periodically calibrate and align the printer to ensure accurate and consistent prints. Follow the manufacturer's instructions for calibration procedures and use appropriate tools for alignment.

Software Updates: Keep the printer's software and firmware up to date by installing the latest updates provided by the manufacturer. These updates often include bug fixes, performance improvements, and new features that can enhance the printer's functionality.

Preventive Maintenance: Implement a preventive maintenance schedule to address potential issues before they become major problems. This may include regular inspections, lubrication of moving parts, and replacing worn-out components as necessary.

Manufacturer Support: Establish a good relationship with the printer manufacturer or authorized service providers. Seek their assistance for complex maintenance tasks, troubleshooting, and obtaining genuine spare parts when needed.

Printing Test to Check the Condition of the Printhead: We suggest you perform a print head test at least once a week, which is usually available in the printer's control software. With this feature, you can check the status of the print head. If the print head is not in good condition, I recommend performing a print head maintenance process.

Climate Condition Effects: In addition, climate conditions in different regions can also affect the maintenance cycle of the printhead. For example, in hot or cold climates, it is necessary to pay more attention to the condition of the printer, because the ink will quickly dry or settle. This does not mean that long periods of non-use or lack of maintenance will cause damage to the printer, but rather to ensure that the printer can maintain its optimal condition and print reliably.

Our Certificate

Below are our certificate:

Our Factory

Below is our factory:

Ultimate Guide

Hot Tags: TFP1000 Automatic 3D Floor Printer Machine, China TFP1000 Automatic 3D Floor Printer Machine manufacturers, suppliers, factory, wall 3d printer price, wall mural printing machine factory, Customized wall wallpaper printing machine, wall and floor print machine factory, digital wall printer machine manufacturers, Customized wallpaper printing robot