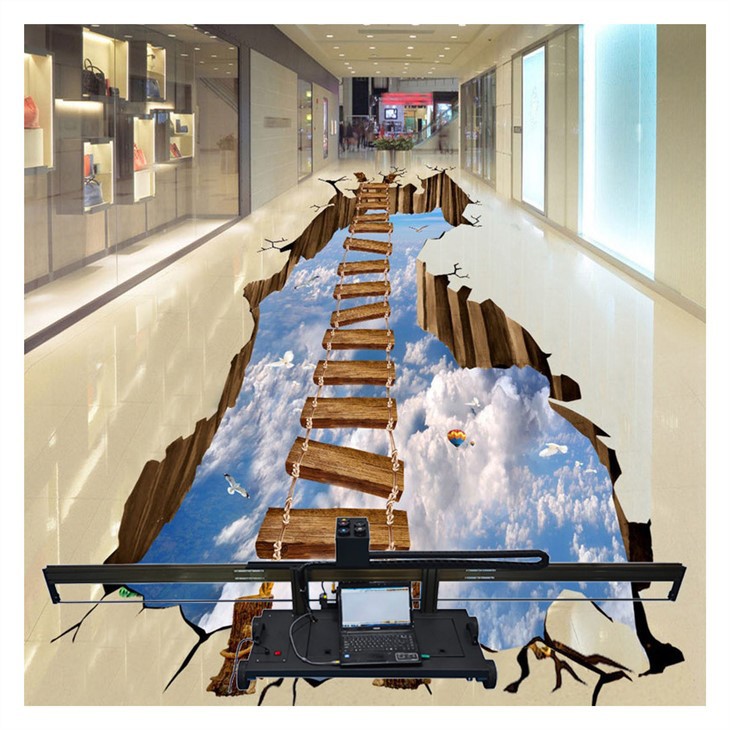

High Speed 3D UV Floor Printing Machine

A MORE ECONOMICAL AND ECOLOGICALLY SUSTAINABLE WAY TO DECORATE ON FLOORS

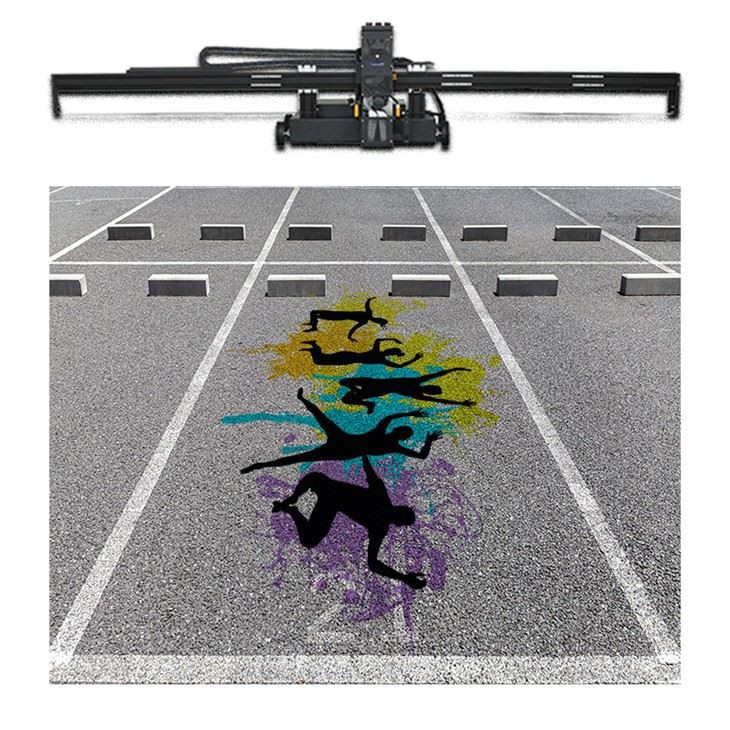

Unlike printing on sticky PVC wrap and expensive labor of installation, and hiring expensive hand-painted arts to directly graffiti on the ground. Tanyu TFP1000 Floor Printer can directly print in full color on cement roads, brick roads, asphalt roads, metal panels and other materials. Tanyu TFP1000 Floor Printer uses environmentally friendly UV inks, which can restore the colors and details of pictures with high quality.

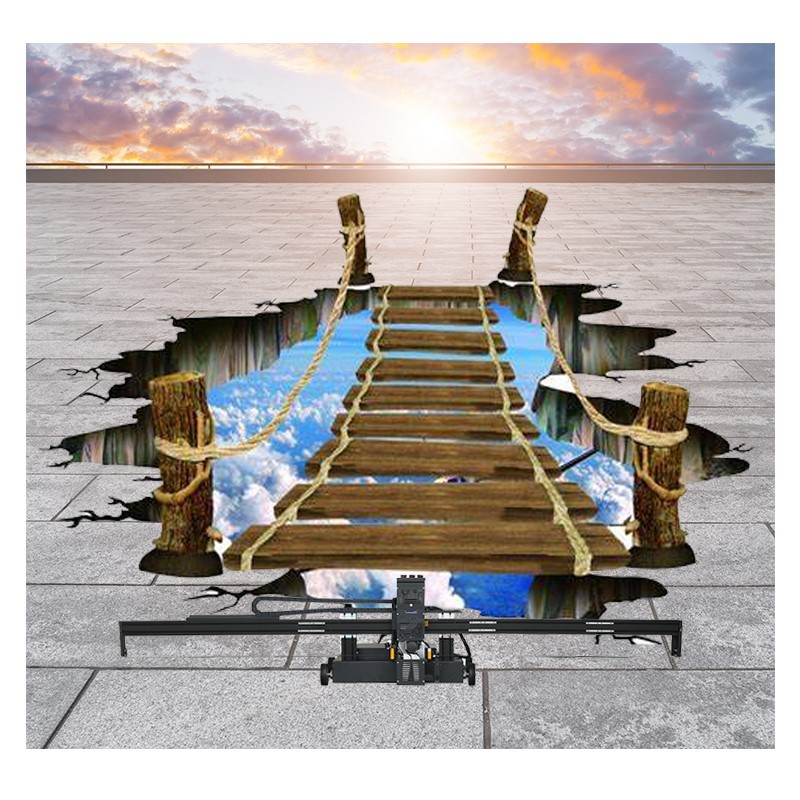

DIRECT DIGITAL INDUSTRIAL PRINTING ON HORIZONTAL FLOOR SURFACES.

The Floor Printer ("TFP") is a unique full color digital printing system specifically designed to digital paint any graphics onto floor surfaces. Tanyu TFP1000 Floor Printer employs UV technology to print on multiple material floors including Wood floor, cement, ceramic tile, asphalt road, brick, lime,Epoxy resin etc.With the help of tracing system, the Tanyu TFP1000 Floor Printer can print on curved and uneven brick surfaces.

PRINTING ON UNEVEN SURFACE

In order to ensure print quality, The Floor Printer has installed two high-precision sensors that can automatically sense the distance between the print head and the ground. Even on uneven floors, the print head will automatically shrink (up to 120mm) to maintain the best distance from the floor to ensure the best print quality.

Applying on Various Substrates

The Floor Printer adopts LED UV printing technology, which can print on various materials. Such as: wooden floor, ceramic tile, brick pavement, plastic, cement, plastic, ceramics and so on. You only need to place it on the ground, set the parameters, and Tanyu TFP1000 Floor Printer will automatically print out the image you need.

Tanyu Technology: a Professional Automatic Floor Printer Manufacturer

Our company was established in 2012 and is an innovative enterprise focusing on the field of wall painting technology.

Variety of Products

We are committed to providing customers with high-quality wall painting machines and large-format wall decoration solutions. Our products include wall printers, floor printers, wall and floor all-in-one printers, vertical 3D wall printers, vertical wall printers with wheels, etc.

Strong Production Capacity

We have two professional production lines and an independent R&D department. We can provide customers with customized machines and improve equipment as the market changes. Usually, it only takes 5 days for standard machines to be delivered, and 9 to 12 days for customized machines.

Strict Quality Standards

All the suppliers we work with are world-class. Each machine has precise assembly process and strict time control. At the same time, we will conduct strict testing and inspection on each machine before shipment to ensure quality and reliability.

Multiple Professional Certifications

At present, we have many international certifications such as ISO9001 certification, CE certification, SGS certification, etc., and have also obtained more than 10 patent certificates. We have provided services to 1000 customers and received good reviews.

High Speed 3D UV Floor Printing Machine

TANYU advertising floor printer can print directly on the floor, the machine width can be customized according to customer requirements.

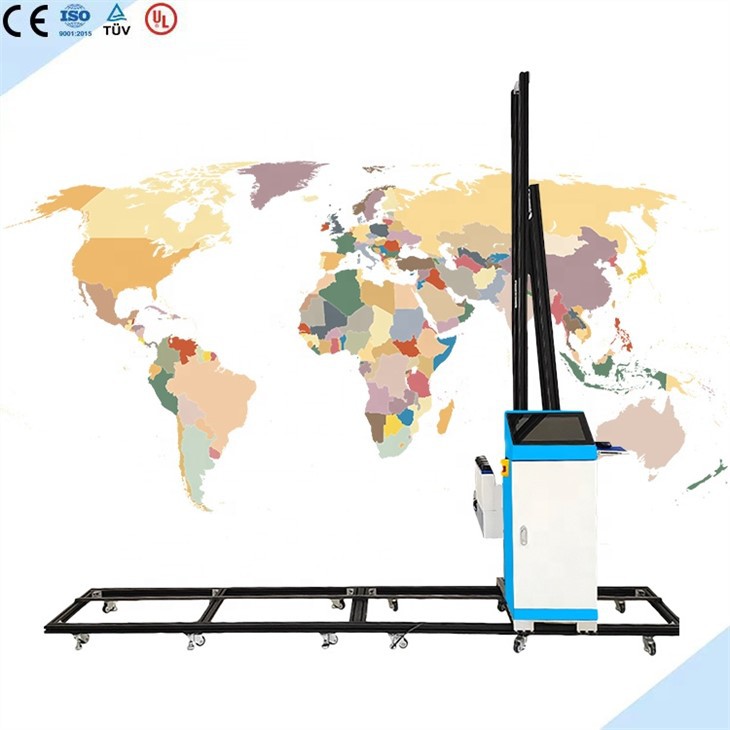

3D Wall Inkjet Printer With Track

3D Wall printer machine is a new way of vertical printing. From signage to original art, our printers can quickly create any durable murals on any surface, indoor or outdoor. It is a vertical printer using UV ink and can print on any flat vertical surface such as cement wall, putty wall, plaster wall, shell powder wall, tile wall, brick wall, acrylic board, glass, etc.

3D Vertical Wall Printer With Wheel

TWP1000 series wall-mounted printer is a portable wall printer developed by us in 2018. It is suitable for indoor printing as well as outdoor with flat surface and no strong wind. TWP1000 series printers are equipped with wheels for easy transportation. They are small and light enough to fit directly into the trunk of a car.

Intelligent Low Ink Consumption Durable Wall Mural Printing Machine

The Wall Painting Machine is equipped with a powerful motor and durable epson print head .Its efficient operating system ensures that the ink spray is even and consistent on all surfaces. This innovative printer is easy to use, efficient, and produces high-quality prints with vibrant colors and stunning details.

Vertical 3d Cmykw Uv Wall Printer Machine Price

The TPP1000 Wall Printer is a cutting-edge and versatile printing machine designed to transform interior spaces with high-quality, custom graphics and designs directly on walls and other large surfaces. This innovative wall printer offers a wide range of features and capabilities that make it a powerful tool for interior designers, decorators, businesses, and artists.

3D All In One Wall And Floor Printer

Wall printer is used to print pictures directly on the wall or the ground, which can replace part of the manual drawing pictures on the surface, speed up the decoration, and can give you a beautiful world. You can use it to decorate your living room, bedroom, children's room. You can use it to paint the walls of restaurants and hotels, or use wall printers to decorate kindergartens.

High Resolution UV Floor Printer Machine

The floor printing machine can print any format photo in any size, printing resolution up to 1440x 2880dpi. If want to protect the printed photo on floor better, that could paint a layer of epoxy resin varnish. Just input the picture and set the size on the computer desk, and one person can print out colorful patterns.

Automatic 3D Floor Printer Machine

Floor printer is a new digital printing system designed specifically to draw any graphics on a floor surface. TFP uses UV printing technology to print on floors in a variety of materials, including wood flooring, cement, tile, asphalt, brick, lime, epoxy, etc. With the help of a tracking system, TFP can be printed on curved and uneven brick surfaces.

Outdoor Application Vertical Wall Printing Machine

Outdoor Application Vertical Wall Printing Machine is an efficient, intelligent painting device that can quickly apply graphics, text, images, and other content to walls. It uses digital image recognition technology and an automatic control system to automatically adjust the brushing force and speed, ensuring precise and high-quality results.

The world of digital printing has undergone a revolutionary evolution in recent years. The floor printer is one of the most important representatives of this evolution. Offering an innovative solution for professionals struggling with the limitations of traditional printing techniques, these printers attract great interest, especially at the intersection of UV printing and 3D printing technologies. An automatic floor printer is a printer, usually designed for industrial use, with the ability to print directly onto floors or other large surfaces. These printers are used in many areas such as advertising, interior design and event organisation. Thanks to UV printing and 3D printing technologies, it is possible to realise printing projects that were previously difficult to imagine.

Fast Results: It is much faster than traditional floor painting methods. It can complete even large floors in a short time.

High Accuracy: It offers a high accuracy rate in transferring digital designs to the floor.

Flexible Design Options: You can personalise your floors with photos, logos, text or customised designs.

Low Cost: In the long run, it is more economical than traditional painting methods, especially in large projects.

Environmentally Friendly Inks: Many modern floor printing machines favour environmentally friendly water-based inks. With their low VOC (Volatile Organic Compound) content, these inks offer safe use both indoors and outdoors.

Adaptive Sensors: Some advanced machines are equipped with sensors for slopes and irregularities of the floor. Thanks to these sensors, the machine can detect any surface changes on the floor and adjusts the print accordingly.

Automatic Cleaning Feature: Most of the floor printing machines have an automatic cleaning feature to prevent clogging of the ink nozzles after long-term use. This extends the life of the machine and keeps the print quality consistently flawless.

Automatic Floor Printer Parameters

|

Brand |

TANYU |

|

Model |

TFP1000 |

|

Operation method |

Wired printing |

|

Power consumption |

No load 20W, maximum 250W |

|

Negative pressure system |

single color single supply, 5 color ink tank |

|

Print Heads |

Epson Double heads |

|

Support pictures |

Support mobile phone/ digital camera photos and network download |

|

Transport |

Folding |

|

Curved surface tracking |

Hyperboloid Banner sensor, up and down bidirectional sensing |

|

Machine size (mm) |

length 2500*width 500*height 300 (Can be folded in half) |

|

Noise |

Standby<20DBA, drawing<72DBA |

|

Print size |

Width 2.5m, length unlimited |

|

Wall surface |

Interior and exterior wall putty wall, latex paint wall, white, imitation porcelain wall, rice paper, canvas, wall clothing, painted glaze, Shell powder, colorful paint, etc. wall glass, ceramic tiles, wooden boards, acrylic, PVC and metal plates, etc. |

|

Print resolution |

360X720DPI/720X720DPI/720X1080DPI/720X1440DPI/1440X2880DPI |

Benefits of Automatic Floor Printers

Increased Efficiency

Automatic floor printers are designed to streamline the printing process, reducing the need for manual intervention. They can handle repetitive tasks, such as loading media, aligning prints, and adjusting settings, with minimal human involvement. This automation increases efficiency while also helping to reduce errors caused by the human factor.

Enhanced Precision and Consistency

Automatic floor printers are equipped with advanced technologies and precise mechanisms that ensure consistent and accurate printing results. They can precisely position prints, apply ink evenly, and maintain consistent print quality throughout the entire project. This level of precision is difficult to achieve consistently with manual printing methods.

Time-Saving

Automatic floor printers can significantly reduce printing time compared to manual methods. They have higher printing speeds, faster drying or curing times, and the ability to handle multiple prints simultaneously. This enables faster project completion, shorter turnaround times, and increased productivity.

Versatility and Customization

Automatic floor printers offer a wide range of customization options. They can print on various flooring materials, including wood, tiles, concrete, and carpets, allowing for versatile applications. Additionally, these printers often support the printing of intricate designs, patterns, logos, and even personalized content, enabling customization to meet specific client requirements.

Cost-Effectiveness

While automatic floor printers may require a higher initial investment, they can result in long-term cost savings. These printers minimize material wastage, reduce labor costs, and optimize ink usage due to their precise control and automation features. Additionally, their high printing speeds and productivity contribute to increased output, generating more revenue for businesses.

Unlimited Print Size

The automatic floor printer offers limitless possibilities when it comes to print size. While the width is unrestricted, the length is typically limited to 4 meters. However, some floor printers can print beyond this length. As technology advances, we anticipate that both the height and width will become limitless, offering even more flexibility for your printing needs.

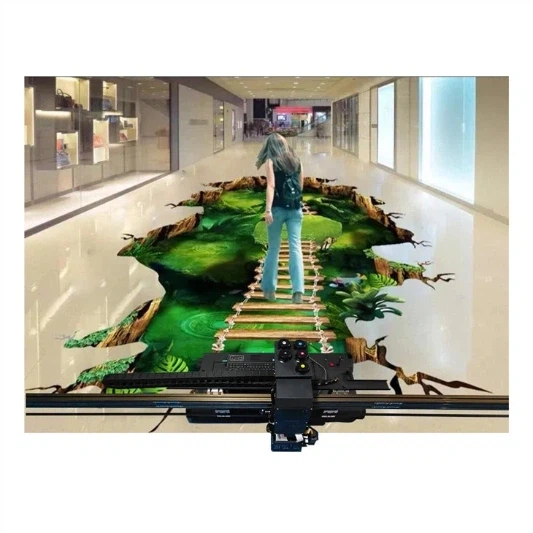

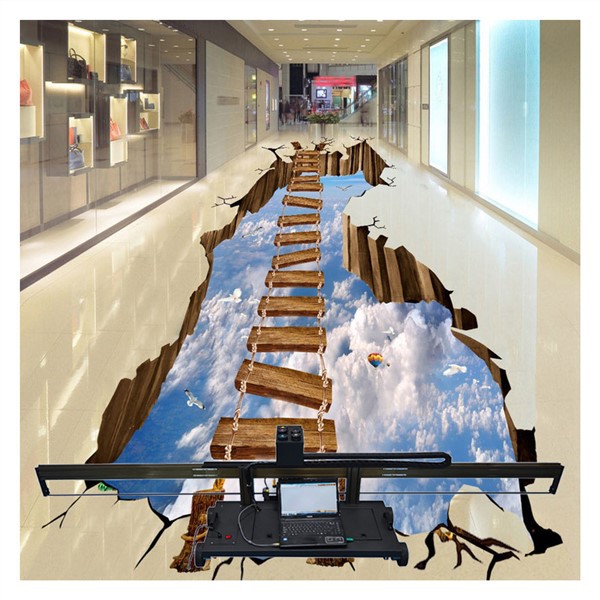

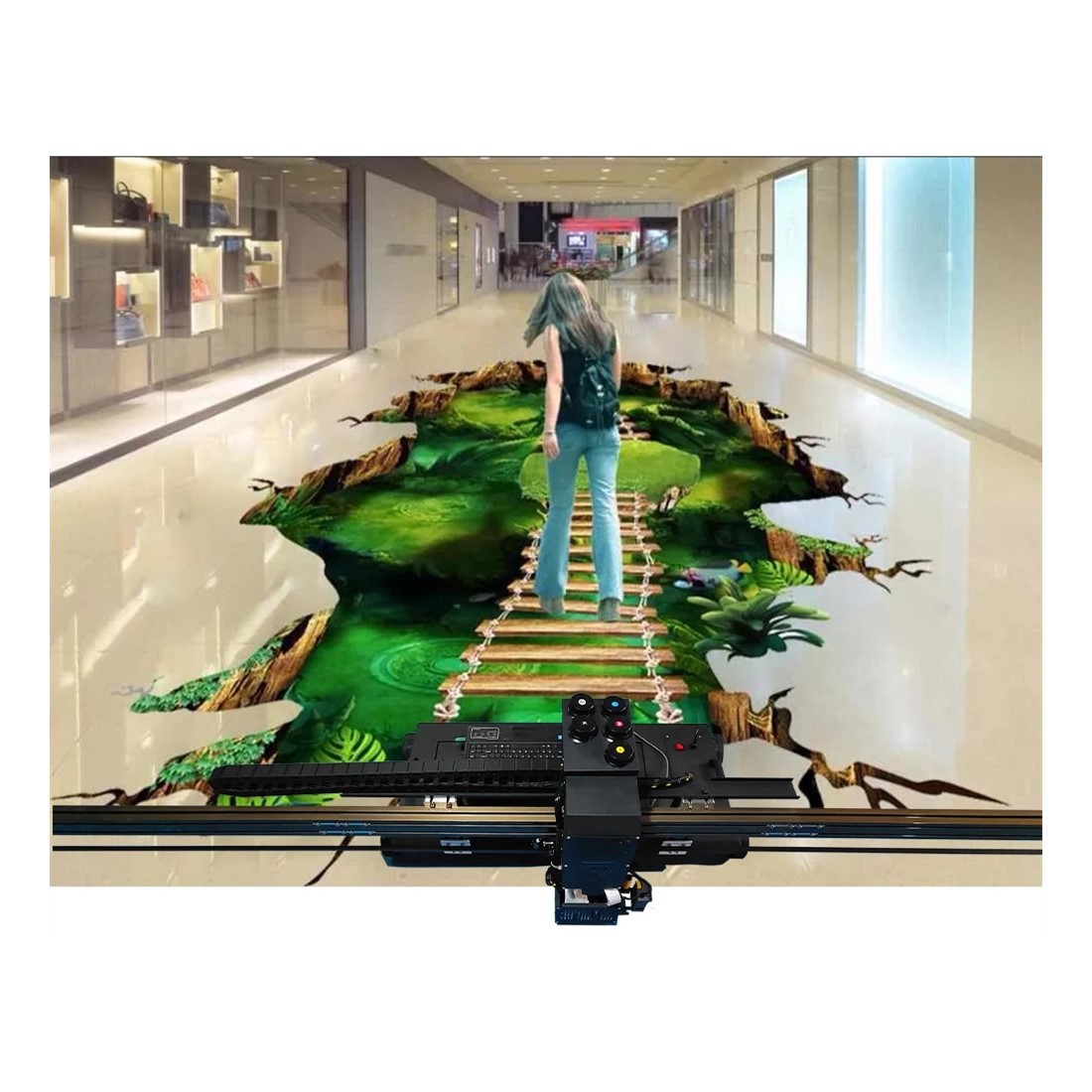

In this section, we will talk about the floor printing machine, which is as popular as the wall printing machine. The floor printing machine is ideal for printing high quality images on floor surfaces. In places such as shopping centres, airports, hotels and restaurants, the ambience of the space can be increased by adding original designs to the floor.

Educational Institutions and Cultural Venues

Museums, art galleries, schools and universities can effectively present their educational and cultural content to visitors and students thanks to the floor printer. It is possible to visualise historical events, artistic works or educational materials through these machines.

Fairs and Events

Exhibition stands, conferences and special events can be made more impressive thanks to the floor printer. Thematic images of the brand or event can be printed quickly and in high quality using these machines.

Road and Car Park Prints

Thanks to the floor printing machine, it is also possible to print on large areas such as roads and car parks in cities. These prints can be used for orientations, promotions or simply for aesthetic purposes. Especially in tourist cities, such prints are extremely useful for orienting tourists.

Sports Halls and Stadiums

With the floor printer, gyms, fitness centres and stadiums can print their own logos, team colours or motivational messages on walls and floors in high quality. Thus, a more energetic and motivating environment can be offered to athletes and spectators.

Hospitals and Health Institutions

Healthcare organisations can benefit from a floor printing machine to provide a calmer and more peaceful environment for their patients. Natural landscapes, relaxing colours and positive messages can boost patients' morale. At the same time, with the floor printing machine, patients and visitors can be prevented from getting lost by making directions in hospitals.

Airports and Terminal Buildings

Airports around the world welcome millions of travellers. In these large spaces, impressive visuals and passenger guidance can be created with wall and floor printers. Thus, both an aesthetic appearance is gained and passengers move more comfortably at the airport.

Shopping Centres and Stores

Shopping centres and stores can use wall and floor printers to offer customers a unique shopping experience. Especially in large shopping centres, special campaigns or events can be promoted with wall prints. With floor prints, discounts, special offers or in-store orientation can be easily realised.

Cinema and Theatre Halls

In these venues where artistic performances are held, play or film posters, show programmes and special events can be printed on the walls with a wall printing machine. In this way, an impressive vision can be presented to the visitors and interest in the events can be increased.

Here's a breakdown of the terms that you'll run into as you learn about floor printers.

*Inkjet: A method of computer printing that sprays colored inks onto paper.

*CMYK: The four primary inks used in color printing: Cyan, Magenta, Yellow and Black.

*Substrate: The floor mural printing surface.

*Print Size: The actual size of the image after being printed.

*Dot: A droplet of ink on the substrate.

*Pixel: The smallest unit of a digital image.

*Resolution: The number of pixels that an image contains.

*DPI: Dots per inch, the number of individual dots that can be placed within one inch of a printed image.

*PPI: Pixels per inch, the number of pixels that can be placed within one inch of a digital image.

Drying time: The time required for ink to dry after spraying to the substrate.

Keep Your Eyes Open

You'll find quite a few floor printer brands out there. Yet what some do are one-time deals. They sell out the printer but might not be able to provide after-sales service. What's worse, the printer looks pretty normal from outside but can't print as expected. This is likely because some of the parts equipped is just for decoration. Or their control program is not working well. You do want to choose wisely.

Pre-shipment Inspection

Inspection before shipment is essential. Not only should each part look good, but also the whole set could perform at its best. Printing test it is. Generally, it takes 24 to 48 hours. This is a step that any reliable supplier will not avoid.

Training and Technical Support

As you saw, this machine is really something. But before you get started, you'd like to know how to work with it very well. Your supplier should prepare you for this. So check out the training materials that come with your purchase. They can be videos or mannuals. In which you'll learn how to set up the printer. Start the machine - Import an image - And print your first piece. It's equally important that you can reach out to them in later use for troubleshooting.

R&D Capability

Vertical printing technology is still in its progress. The question is: How do you keep your wall printing machine up to date? Cooperate with supplier that has R&D capability.

Automatic Floor Printer Safety Tips

Here are some basic safety precautions to follow when using an automatic floor printer:

Provide comprehensive training to operators on the proper use of automatic floor printers. This should include understanding the machine's functionalities, emergency procedures, and safety protocols. Well-trained operators are more equipped to handle potential risks.

Mandate the use of appropriate PPE, including safety glasses, gloves, and, if necessary, ear protection. This safeguards operators from potential hazards such as splattering ink, noise, or any unexpected events during the printing process.

Maintain proper ventilation in the printing area to minimize exposure to fumes or odors generated during the printing process. Follow environmental guidelines and ensure the workspace meets recommended temperature and humidity levels to prevent overheating or material-related issues.

Ensure that the automatic floor printer is properly grounded and that electrical components are in good condition. Avoid overloading electrical circuits and use appropriate power sources to prevent electrical hazards.

Keep fire extinguishers and other firefighting equipment accessible in the printing area. Establish a clear evacuation plan and conduct regular drills to ensure that all operators are familiar with emergency exits and procedures in case of a fire or other emergencies.

Have a qualified operator present during the printing process to monitor the machine and intervene if necessary. Regular supervision helps detect any abnormalities or issues before they escalate, contributing to a safer working environment.

Our Certificate

Below are our certificate:

Our Factory

Below is our factory:

Ultimate Guide

Hot Tags: TFP1000 High Speed 3D UV Floor Printing Machine, China TFP1000 High Speed 3D UV Floor Printing Machine manufacturers, suppliers, factory, China custom wallpaper printing machine, Customized print on wall machine 3d, wallpaper printing robot machine, wall mural printer machine, 3d vertical wall printing machine factory, wall printer machine factory